Nitrile gloves have good chemical resistance, which means they are indispensable for practical use in the chemical industry

Nitrile gloves have good chemical resistance, which means they are indispensable for practical use in the chemical industry

In this article, you will learn about chemical nitrile gloves, evaluation criteria, when to use nitrile gloves, and everything you need to know.

Why do nitrile gloves have excellent chemical resistance?

The butadiene-acrylonitrile copolymer material has a great influence on the chemical resistance of nitrile gloves. This material makes your nitrile gloves highly resistant to chemicals such as acetic acid and alkali.

In addition, materials such as synthetic rubber are also included to make it, which has abrasion resistance, strength, good flexibility and puncture resistance, making it more suitable for industries such as chemical handling, laboratories, etc.

What Chemicals Are Nitrile Gloves Chemicals Resistance To?

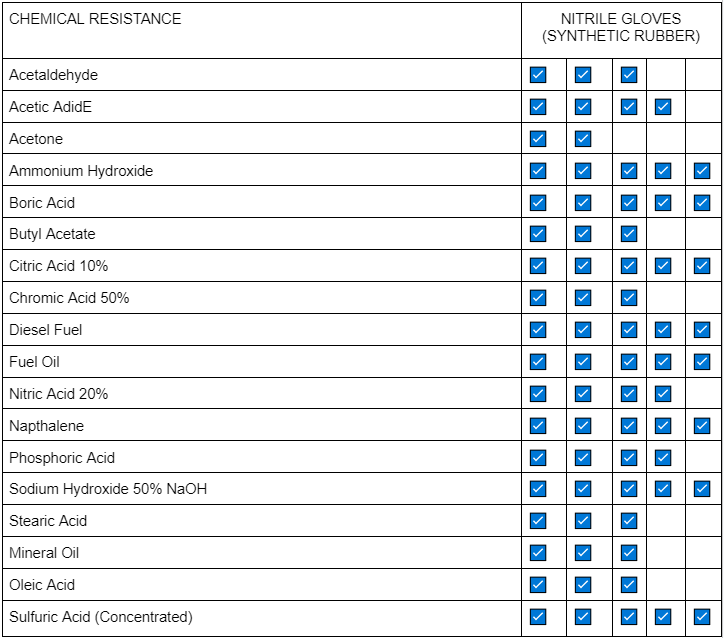

Chemical resistance nitrile gloves are highly resistant to the chemicals below:

- Weak acids

- Weak caustics and alcohol

- Household detergents

- Vegetable oils

- Petroleum products

- Fuels

- Greases

- Organic solvents

In addition, according to the EN374 standards here is the list of the chemicals nitrile gloves will help you resist:

- Acetic acid 10%

- Chlorhexidine digluconate 4%

- Ethanol 20%

- Formaldehyde 15%

- Formaldehyde 37%

- Glutaraldehyde 50%

- Hydrogen peroxide 30%

- Nitric Acid 10%

- Nitric Acid 36%

- Paraformaldehyde 50%

- Phenol 1%

- Povidone iodine 10%

- Sodium hydroxide 40%

- Sulphuric acid 47%

NOTE: You should consider removing the nitrile chemical gloves with care when they contact any kind of hazardous substance.

Nitrile Gloves Chemical Resistance Chart

What industries are suitable for nitrile gloves?

Particularly useful are mechanical maintenance and manufacturing, automotive maintenance, chemical industry, biomedical research industry, and all chemical research industries.

Nitrile Chemical Resistance Glove Evaluation Standard

When you expose the gloves to chemicals, they will be judged according to this standard.

Breakthrough Time: If the gloves can withstand the chemical for more than 8 hours before the breakthrough time, the gloves are considered to be of good quality.

However, if the same glove can withstand a chemical for more than 8 hours before the breakthrough time, the breakthrough time may be shorter when you expose it to different chemicals.

Note: Discard the glove immediately when breakthrough occurs because it is no longer safe.

Degradation: This refers to the physical deformation of the gloves, such as shrinking, softening, swelling, cracking and splitting. Degradation occurs when you expose nitrile gloves to solvents such as acetone.

Nitrile gloves degrade faster and sometimes slower, depending on which solvent you expose them to.

Permeation Rate: When breakthrough occurs, the rate at which the chemical passes through the nitrile gloves is called the permeation rate.

This rate is broken down into three, namely surface absorption, material diffusion, and inner surface desorption.

If your nitrile gloves are thicker, the chemical will take more time to penetrate. But if the gloves are thinner, it will take less time. This means that thicker nitrile gloves have lower permeation rates.

Note: Be aware that nitrile gloves you wear or are pressurized offer less protection.

Conclusion

In conclusion, chemical resistant glove nitriles are the most protective and long-lasting gloves capable of resisting a lot of chemicals like fuels, greases, weak acids, etc. By now, you should have digested enough information that will help you make an informed decision when you want to buy chemical resistant nitrile glove.