Criteria Consideration for Massive Production Quality

At the Aibon Safety® factory, high quality has always been our pursuit, and quality is at the core of our development. Winning the trust of customers is also due to our high quality and strict safety standards. We strictly carry out production according to the samples confirmed by customers. During the production process, we strictly control every step from raw materials, quality, packaging, shipping and other aspects. Every aspect should be paid attention to to ensure the perfect safety glove solution.

Aibon will conduct measurable standards for product quality based on the glove AQL standard. Production batches must follow the measures in ISO28590-1, commonly called AQL tables, to calculate the sample size and the AQL limits based on the inspection level chosen. That level should be appropriate to the situation and products. which is a product test for many production properties of gloves, such as water lifting, inflation and tension testing, and needs to be clearly specified The program conducts random testing of products in manufacturing. The tested samples have specified standards and specifications. The general household and industrial grade indicators are AQL4.0g. The medical grade standards are divided into AQL1.5 and AQL2.5. Surgical gloves require more Low AQL0.65. Learn more about our order process and quality control as below.

| Purchaseing Produce | Order process | Manufacturing | Delivery |

| 1.Customer needs identification Free sampels confirmation 2.Confrim purchase order | 1.Pre-production samples manufacturing 2.Sampels confirmation | 1.Provide comparison of prenatal samples and confirmation samples 2.A 100% comprehensive inspection | 1.QA random inspection before shipment 2.Transport by ship、train、air 3.After- sales service |

Air Testing

The process of air testing involves inflating to detect pinholes. It applies a certain amount of pressure to find the tiniest perforations. We have been improving the process and have now upgraded to light detection. This has many benefits, such as being able to find tiny perforations, and also detecting flaws and latex particles inside the gloves. , this operation improves efficiency, and the most important thing is to ensure the quality of the product. We all pass the 100% full inspection system because we attach great importance to the product quality and brand reputation of our customers.

Moreover, this testing involves some manual practice techniques. Gloves are positioned in front to check any potential air leaks directly.

Weight and Thickness Testing

Ensuring the weight and thickness of gloves is a critical step in our entire process. It begins with precise preparation when assembling the vulcanization package, where we carefully proportion raw materials based on the order’s weight requirements. Once the gloves are on the production line, our skilled workers conduct random weight checks to identify any discrepancies.

To promptly correct any gram weight errors, we adhere to specific tolerances: dip flocklined latex gloves and spray flockline gloves below 80g allow for a variation of +/-2g, while those above 80g permit +/-5g, and spray flocklined household gloves allow +/-3g. During the dry process, we continue to monitor weight and conduct thickness testing, repeating these confirmations before packaging to ensure that they align precisely with the customer’s order specifications.

Before we proceed to packaging, we double-check the weight and thickness of the packaging material itself. This meticulous process is essential because we are committed to delivering complete and accurate orders to every customer, ensuring their satisfaction with our products.

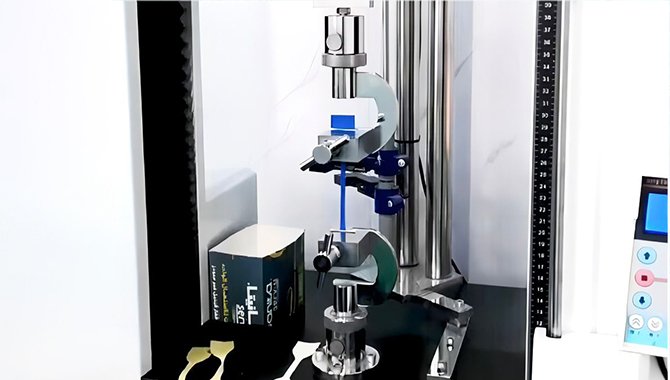

Elongation Stress Testing

According to customer needs, we provide customized latex content, such as 70%, 80%, 90%, etc. Different latex content will have different tensile strength. Mexican law requires that the englongation needs to reach 700%. Generally, we will pass this test for customized products. In this test, an extension procedure is employed to assess the gloves’ tensile strength. It’s imperative that the gloves can withstand exceptionally high levels of stress, ensuring the utmost safety. This test serves as a robust indicator of the gloves’ durability by measuring their resistance to tearing. Additional factors, such as production monitoring, ongoing quality control, and tear time, are also taken into consideration.

AIBON Gloves Standard Quality

AIBON manufactures custom gloves with an unwavering commitment to strict quality control and rigorous adherence to PPE (Personal Protective Equipment) standards, according to PPE REGULATION 2016/425 CATEGORY Iour products has passed CE420, CE388, CE374 and ect. As a certified and approved company, you can rely on us for top-notch glove solutions. Don’t hesitate to reach out with your inquiry today!