Food Gloves

Food handling gloves are gloves designed specifically for the food industry to maintain hygiene and prevent contamination during the handling, preparation and serving of food, while protecting the user from cuts that can be caused by knives and other dangerous tools. One of the main reasons to use food gloves is to prevent contamination. Gloves act as a barrier between the food handler’s hands and the food, reducing the risk of transferring bacteria, viruses or other contaminants. Here are the features food gloves must have.

- Non-toxic

- Handling flexibility

- Comfortable to wear

- Cut resistant

- Oil resistant

- Water and oil resistant

- High handling performance

Custom Food Gloves Manufacturer in China

AIBON manufactures a wide range of food contact gloves suitable for numerous food processing projects. This includes food preparation, heavy duty fish, chicken, and even meat processing. Additionally, we can design precise gloves to keep areas sanitary and protect workers. In addition, there are a variety of sizes, colors, materials and strengths to choose from, such as nitrile, latex, vinyl, PE, and knitted ones.

Our company also has skilled workers to ensure consistent delivery times and can customize your food glove requirements. Customization includes size, color, weight, material, and even your corporate branding, products comply with food contact, let us understand your needs, we will ensure you are satisfied with the quality, cost and quick return.

Contact us today!

Proper Use Protocol

Specific guidelines must follow for using gloves in food service.

Below is a list of what they are.

- Washing hands before wearing the gloves

- Changing the gloves once every four hours

- It’s required to wear a new one when working on different food duty

- Do not wear gloves that are torn or damaged.

- Removing gloves after preparing raw poultry, raw meat, or seafood

- Putting on a new one while making ready-to-eat meals

- Quality Guidelines

- Food Glove Stability Sample

| Food Glove | |

| Manufacturing Under: | Complies with: |

| ISO 14001 | ASTM |

| CE EN 420 | |

| ISO 9001 | CE EN ISO 21420:2020 |

| Food Types | Latex Glove | Vinyl Glove | Nitrile Glove |

| Liquor | partially suitable | partially suitable | suitable |

| Vegetables | partially suitable | suitable | suitable |

| Meat | partially suitable | not suitable | suitable |

| Seafoods | suitable | partially suitable | suitable |

| Saturated Fat | partially suitable | not suitable | suitable |

| Pastries | suitable | suitable | suitable |

| Aqueous | suitable | suitable | suitable |

Related Products

Food-Grade Materials for Gloves

For ideal gloves in food-related processing, here are the most in demand.

Polyethylene Gloves

Polyethylene gloves are lightweight and often used for short-term, low-risk tasks. They are commonly used in the food industry for tasks such as sandwich preparation.

Latex Gloves

Latex gloves are a traditional choice for food handling. They provide a high level of dexterity and tactile sensitivity. However, some individuals may have latex allergies, so alternatives like nitrile or vinyl are often preferred.

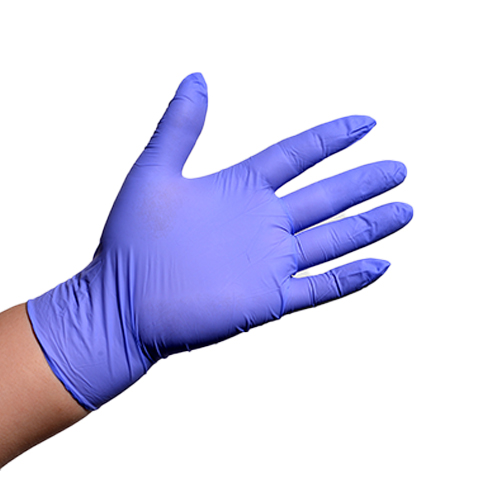

Nitrile Gloves

Nitrile gloves are a popular choice for food handling because they are latex-free and provide excellent resistance to punctures and chemicals. They are suitable for individuals with latex allergies and are known for their durability.

Vinyl Gloves

Vinyl gloves are another latex-free option. While they are less elastic and may provide a looser fit compared to latex or nitrile gloves, they are economical and suitable for short-duration tasks.

Standard Criteria in Selecting Food Gloves

Before placing an order, some factors indicate a quality needs to recognize. Check the following details below to get the best glove for food service.

- AQL level

- Right-fit gloves on hands

- Colorization

- Its wall thickness

- CE marking protection label

- Material

Allergy Reaction Awareness

Since food handling is the primary concern, identifying potential linked problems has to be considered essential. That includes even the gloves material. They have the risk of causing allergic reactions.

Therefore, in such cases, food preparation or processing should not be done while wearing a latex glove. It could result in a minor or severe allergic reaction. Taking advanced safety measures is necessary to avoid incidents.

There are, however, some gloves that are excellent for this field. Nitrile and vinyl gloves are a reasonable substitute for latex. They are both hypoallergenic gloves. Select a latex and powder-free glove to ensure total protection against allergens.

Choose the right material food gloves

Choosing the right food gloves is crucial to ensure food safety, hygiene, and compliance with regulations. Here are some key factors to consider when selecting food gloves:

- Material:

- Choose gloves made from food-grade materials such as latex, nitrile, vinyl, or polyethylene. Consider any allergies that users may have, and select gloves accordingly.

- Allergen Information:

- Be aware of common allergens associated with glove materials, especially latex. If allergies are a concern, opt for latex-free alternatives like nitrile or vinyl.

- Intended Use:

- Consider the specific tasks for which the gloves will be used. Different glove materials and types are suitable for various applications, such as food preparation, handling raw meats, or cleaning, the nitrile glove are most durable.

- Thickness:

- Choose the appropriate thickness based on the tasks and level of protection required. Thicker gloves provide more durability and protection but may reduce tactile sensitivity.

- Powdered vs. Powder-Free:

- Decide whether to use powdered or powder-free gloves. Powdered gloves can be easier to put on, but powder-free gloves are preferred in environments where powder contamination is a concern.

- Size:

- Ensure that the gloves are available in various sizes to accommodate different hand sizes. Proper fit is essential for comfort and functionality.

- Durability:

- Assess the durability of the gloves based on the expected duration of use and the tasks involved. Thicker gloves are generally more durable.

- Comfort:

- Choose gloves that offer comfort during extended use. Consider features like textured surfaces for better grip and ergonomic design.

- Resistance to Chemicals:

- If the gloves will come into contact with chemicals or cleaning agents, ensure they are resistant to these substances to maintain their integrity.

- Cost Consideration:

- Balance the quality of the gloves with your budget constraints. Consider the cost per glove and the value they provide in terms of safety and functionality.

Remember that the choice of food gloves may vary depending on the specific requirements of your food handling tasks. Regularly review and update your glove selection based on feedback and any changes in regulations or industry best practices.