Whether in daily life or workplace settings, nitrile gloves are widely used across various industries due to their exceptional chemical resistance and high durability. This makes them one of the top choices over latex gloves. However, one downside is that nitrile gloves tend to be significantly more expensive than other types of gloves. So, what exactly makes nitrile gloves so costly? This article will analyze the issue from several key aspects.

The Raw Materials of Nitrile Gloves

First, we must start with the raw materials of nitrile gloves. As widely known, nitrile gloves are made from the polymerization of acrylonitrile and butadiene to form poly(acrylonitrile-butadiene) copolymer, also known as synthetic rubber. This material is then processed with specialized plasticizers, stabilizers, and other additives.

A key raw material, acrylonitrile, is often referred to as “black gold” in the chemical industry, and its price fluctuations directly impact the market price of nitrile gloves. In 2022, the energy crisis caused by the Russia-Ukraine conflict led to a 23% price increase in acrylonitrile in just one month, which in turn drove up the price of nitrile gloves.

During the global COVID-19 pandemic, nitrile gloves, once an overlooked protective product, saw a dramatic price surge of 300%-400%. Even today, their prices remain high at around $80-$150 per thousand gloves.

The Complex Production Process of Nitrile Gloves

The entire manufacturing process of nitrile gloves is highly intricate, which significantly increases production costs. The production line, stretching up to 200 meters, operates under strict temperature and humidity controls, ensuring a precise temperature of 45℃ ± 0.5℃. Such high-precision equipment alone costs millions of dollars.

Moreover, stringent quality inspections add to the hidden costs that guarantee the superior quality of nitrile gloves. The complex manufacturing process includes multiple intricate procedures such as dipping, vulcanization, and surface treatment, all of which further elevate production costs.

Key Steps in Nitrile Glove Production

Synthesis: The first step involves copolymerizing acrylonitrile and butadiene to produce nitrile synthetic rubber, ensuring excellent chemical and oil resistance.

Mold Preparation: Molds, usually made of ceramic or metal, are cleaned and heated before dipping in a coagulant to enhance adhesion.

Glove Formation: The molds are dipped into nitrile rubber solution to form gloves. For thicker gloves, multiple dipping cycles may be required.

Vulcanization: The gloves are heated in a high-temperature furnace to improve elasticity and strength, followed by cooling to stabilize their shape.

Demolding: Water and air assist in removing the gloves from the molds.

Surface Treatment: Gloves undergo chlorination or powder treatment to reduce friction and enhance grip.

Advantages of Nitrile Gloves

Despite their high cost, nitrile gloves offer numerous advantages that justify their price. Below are some key benefits:

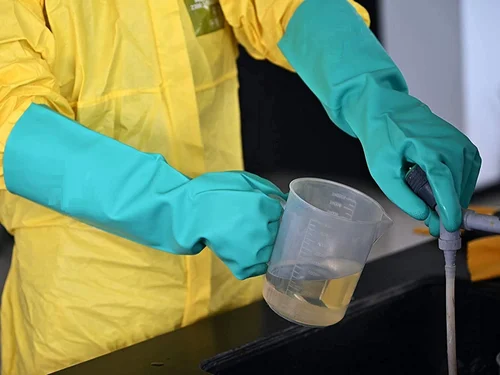

Chemical Resistance

Nitrile gloves provide outstanding resistance to various chemicals, including oils, acids, alkalis, and solvents. They perform exceptionally well in oily environments and offer superior protection compared to latex gloves, making them ideal for handling hazardous materials.

Latex-Free

Since nitrile gloves do not contain latex proteins, they eliminate the risk of allergic reactions associated with natural latex, making them an excellent alternative to latex gloves.

Durability

Nitrile gloves are highly resistant to mechanical damage, making them more durable than other glove types. This reduces the need for frequent glove replacement.

Powder-Free Design

Many nitrile gloves feature a powder-free design, minimizing contamination and making them ideal for food processing and medical applications.

Varied Thickness Options

Nitrile gloves come in different thicknesses, ranging from lightweight to heavy-duty, catering to diverse industry needs.

Stringent Certifications for Nitrile Gloves

Every type of glove requires certification, but nitrile gloves undergo even stricter regulations, especially disposable nitrile gloves. To enter the European and American medical markets, nitrile gloves must pass multiple certifications, including FDA, CE, and ISO1.

In particular, the U.S. FDA conducts rigorous on-site inspections, even assessing the air cleanliness of factory dressing rooms. The certification process takes at least six months and costs tens of thousands of dollars. The Japanese PMDA certification requires at least three years of clinical tracking data, resulting in extensive documentation. The EU REACH regulation mandates testing for 223 SVHC substances, with associated testing costs reaching tens of thousands of dollars. These hidden costs contribute to the high price of nitrile gloves.

Supply and Demand Dynamics

Scarcity drives up prices. During the 2020 COVID-19 pandemic, the demand for nitrile gloves surged to unprecedented levels, exposing shortages in global supply. At the same time, the storage conditions for nitrile gloves became as strict as those for vaccines—requiring temperatures of 15-25℃ and humidity below 50%. These conditions further increased costs and led to global supply shortages, driving up prices.

The rising price of nitrile gloves reflects a universal truth: true protection for life is never cheap.

Transportation Costs

Regardless of the destination country, tariffs are an unavoidable factor. Exporting to Europe and the U.S. involves additional transportation fees and customs duties. Recent increases in international shipping costs have further driven up the price of imported nitrile gloves, sometimes multiplying costs several times by the time they reach consumers, especially in today’s unstable supply chain environment.

Strict Quality Control

Nitrile gloves undergo rigorous quality control processes. Each batch must pass at least 20 different tests, including pinhole detection, explosion testing, and chemical resistance analysis. Defective gloves are immediately discarded, reducing the overall production yield but ensuring high product quality. This further adds to the overall cost.

Conclusion

Although nitrile gloves are expensive due to their complex manufacturing process, high-quality materials, and stringent certifications, they offer unparalleled chemical resistance, durability, and protection. For industries requiring reliable protective gear, nitrile gloves are a valuable investment.

For those seeking high-quality nitrile gloves, sourcing from a professional and reputable supplier is crucial. Aibon is a trusted supplier with 15 years of experience in the glove industry. We are confident that we can provide you with the best nitrile gloves to meet your needs!

How to Measure Glove Sizes – Source: AIBON

Latex gloves– Source: AIBON

Safety gloves– Source: AIBON

Working gloves– Source: AIBON