In order to protect the hands in various working environments, safety gloves are commonly worn. Simply put, safety gloves are a basic protective tool used to protect hands, fingers, elbows, and other parts of the hands.

For every industry that requires safety gloves, there are dozens of different products available to meet the needs of the wearer. In this era of rapid technological advancement, workers face greater risks in rapidly changing work environments, making it crucial to have the appropriate safety equipment.

The absence of proper safety gloves can have significant negative consequences for businesses or workers, leading to catastrophic effects for workers and causing them to lose their sense of safety, and sometimes even altering their lives.

What Functions Must Safety Gloves Have?

Safety gloves must not only protect against external dangers but also enable wearers to perform optimally in extremely challenging work scenarios.

Grip

Grip strength is crucial in gloves; if items slip due to insufficient grip strength, it can lead to dangerous accidents.

Fit

In addition to grip strength, the fit of gloves is also important to prevent gloves from becoming cumbersome or restrictive during intricate tasks. Naturally, besides fit, comfort is also necessary, ensuring that the materials used are not harmful to the skin or do not cause skin conditions.

Wear Resistance

Abrasion resistance is also one of the essential properties of safety gloves, making them more practical and durable, thereby avoiding frequent replacements due to minor damage.

Breathability

The importance of breathability varies depending on the type of gloves and individual needs, but generally, allowing airflow while preventing hazards from entering is equally important.

Personal use safety gloves for home and garden come in hundreds of varieties, but safety gloves are more commonly used in construction sites, building operations, and other workplaces to protect workers from various dangers.

Types of Safety Gloves

Each type of safety gloves is different and serves different purposes, making them crucial for users. Therefore, it is necessary to understand the types of safety gloves, but due to the diverse range of safety gloves available, we will list some common types for you to choose from.

General Safety Gloves

General safety gloves typically provide functions such as friction prevention, blister and ulcer prevention, and protection against oil irritation. However, since these are general-purpose gloves, their applications vary, but they can be used in most work scenarios.

Chemical Resistant Safety Gloves

Chemical resistant safety gloves protect against various chemicals, liquids, and other corrosive substances. Depending on the strength of the chemicals, such safety gloves must strictly adhere to relevant regulations to ensure proper protection.

Puncture Resistant Safety Gloves

Puncture Resistant Safety gloves prevent punctures from sharp hazardous objects such as nails, screws, and construction debris and can provide corresponding protection and performance based on different needs.

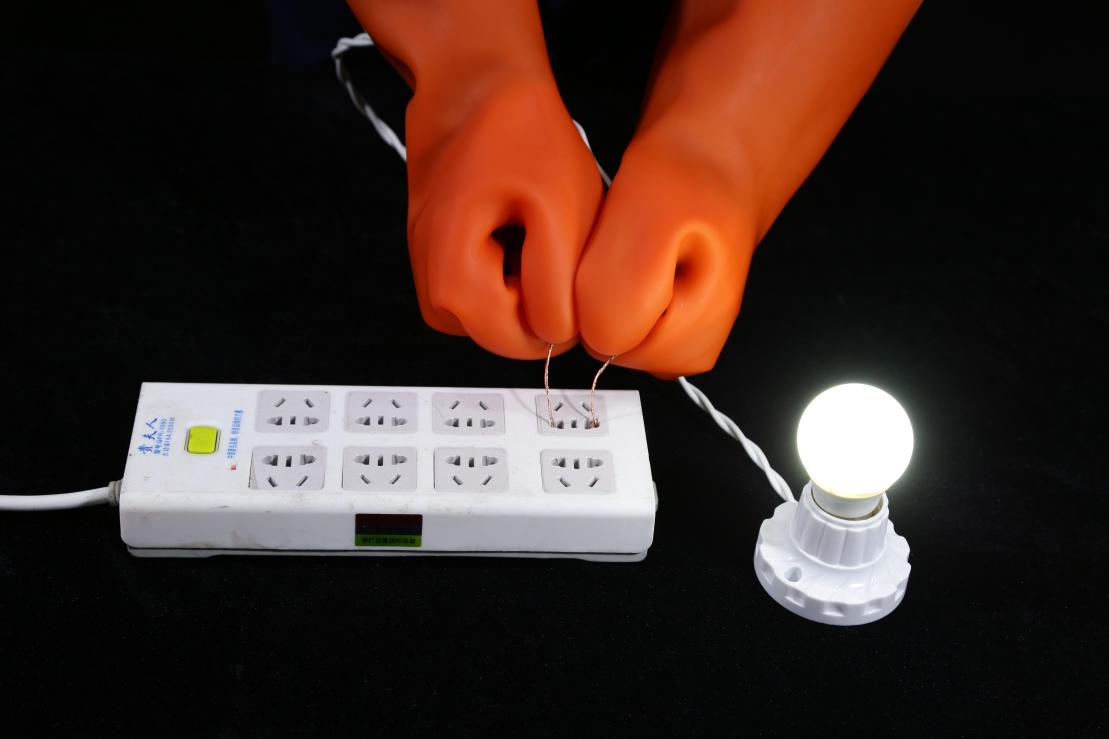

Electrically Insulated Gloves

Electrically insulated gloves are typically made of latex materials and resist different levels of voltage, preventing electric shocks and arc flashes. According to regulations, these gloves must be tested every six months to ensure optimal protection, commonly used in the electric power and electrical maintenance industries due to the dangerous scenarios involved.

Cold/Hot Operation Gloves

Cold/hot operation gloves protect against heat generated by ovens, appliances, welding, and other hot/cold operations. The different types of gloves depend on their use and working environments. Some heat-resistant safety gloves can withstand temperatures of up to 315 degrees Celsius, while some cold-resistant gloves can protect hands in extremely cold environments, such as temperatures below minus twenty degrees Celsius.

Disposable Gloves

Disposable gloves are single-use protective items commonly used in food safety, medical health, and medical equipment to prevent cross-contamination and the spread of pathogens, avoiding the risk of chemical exposure and skin allergies.

Cut Resistant Gloves

The level of cut-resistant gloves is determined by conducting cut machine tests, widely used in various industries, including steel processing, glass handling, wood processing, automobile manufacturing, etc. They are mainly used to prevent injuries to hands from sharp objects such as knives, glass, etc.

For example, cut-resistant gloves used in automobile manufacturing typically need to have corresponding puncture resistance and oil resistance, while cut-resistant gloves used in the food industry may have hygiene control functions and require coordinated or customized colors to prevent cross-contamination of food and food types.

By browsing safety glove websites, you can learn more about these glove categories and others. Each product provides detailed information on its specific uses and hazard protection capabilities. Because of the wide variety of safety glove styles suitable for almost unlimited operational applications, we will strive to provide you with quality products and glove recommendations for your specific scenarios. If you are interested in safety gloves or have any doubts about them, you can contact us anytime, anywhere.

How to Measure Glove Sizes – Source: AIBON

Medical Gloves – Source: FDA

Nitrile Gloves or Latex – Source: AIBON

Medical Gloves Guidance Manual – Source: FDA